The Guide to Magnetic Coercivity

Learn all you need to know about magnetic coercivity.

Introduction to Magnetic Coercivity

Coercivity (coercive force), determines how well a magnet can resist external forces that would cause it to lose its magnetic properties. The forces that can demagnetise, or degauss a permanent magnet include; temperature, alternating currents and kinetic force. High coercivity is necessary for magnets that will be exposed to these forces.

Neodymium magnets, or NdFeB magnets, are very magnetically powerful magnets but they can become demagnetised in temperatures above 80C. This is where samarium cobalt and alnico magnets are useful because they have excellent resistance to demagnetisation forces.

All permanent magnets, (neodymium, samarium cobalt, alnico and ferrite) have a north pole and south pole. Facing two of the same poles repel the magnets and facing opposite poles attract (facing north and south poles).

Coercivity by Magnet Type

Coercivity of Neodymium Magnets

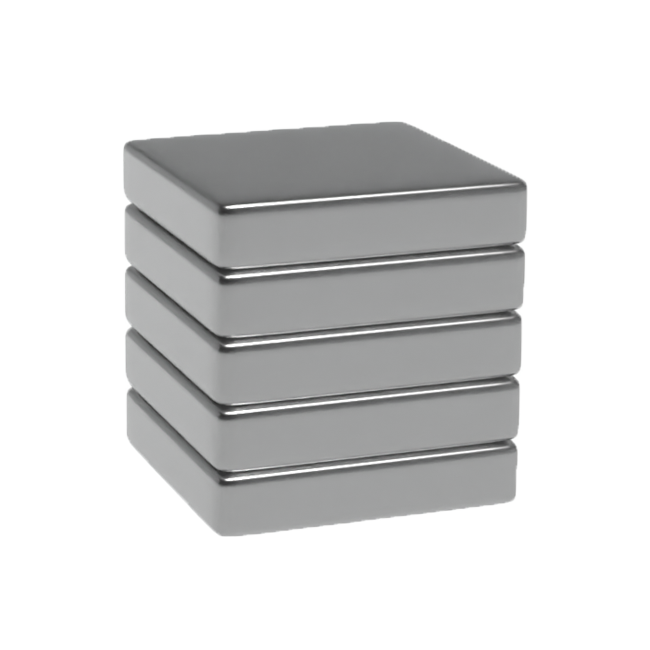

Neodymium magnets are the most magnetically powerful permanent magnets available. These magnets are the most popular magnets that we manufacture because their use-cases are absolutely endless. Not only are they very magnetically strong, but they can be manufactured into almost any shape which makes them incredibly versatile.

The coercivity of neodymium magnets is dependent on the grade you choose. Although many people understand the grades range from est N35 to N52, there are actually many more grades to choose from. If you see a letter after the number, for example, N45SH, the letters indicate the coercivity levels for that magnet. The number after the letter N (e.g. N45) refers to the magnetic power and the higher the number, the stronger the magnet. Below, you can see the heat tolerances for each grade of Neodymium.

No Letter – Max Temperature of 80 °C

N33, N35, N38, N40, N42, N45, N48, N50, N52, N55.

M – Max Temperature of 100 °C

N33M, N35M, N38M, N40M, N42M, N45M, N48M.

H – Max temperature of 120 °C

N30H, N33H, N35H, N38H, N40H, N42H, N45H, N48H.

SH – Max temperature of 150 °C

N30SH, N33SH, N35SH, N38SH, N40SH, N42SH, N45SH

UH – Max temperature of 180 °C

N33UH, N35UH, N38UH, N40UH, N42UH.

EH – Max temperature of 200 °C

N33EH, N35EH, N38EH.

AH – Max temperature of 230 °C

N33AH, N35AH.

This means that some neodymium magnets can withstand temperatures up to 230°C. This works by changing the material composition to include more heat-resistant materials. You can see a full datasheet of all of the neodymium grades by clicking the link below. Generally speaking, neodymium magnets with higher coercivity levels are capable of reaching lower magnetic power than ordinary neodymium magnets.

Coercivity of Samarium Cobalt Magnets

Samarium cobalt magnets are the second most magnetically powerful permanent magnets and have much better levels of coercivity than neodymium magnets. This means they can withstand extreme temperatures and other demagnetization forces without losing magnetism.

We often find people using samarium cobalt magnets in machinery and engines where the environment gets hot. We’ve also known people to use samarium cobalt magnets in ovens. There are many different grades that withstand high temperatures and you can see them below.

Max Temperature of 250 °C

SC-1615, SC-1819, SC-2019, SC-2219, SC-2416

Max Temperature of 300 °C

SC-2228, SC-2428

Max Temperature of 350 °C

SC-2618, SC-2826, SC-3018 and SC-3215.

This means that some grades of samarium cobalt magnets can withstand temperatures as high as 350°C. You can see all of the magnetic properties of samarium cobalt magnets here.

Coercivity of Alnico Magnets

Alnico magnets are the third most magnetically powerful permanent magnets after samarium cobalt and neodymium magnets. These magnets have the best levels of coercivity and can withstand extreme demagnetisation forces. There are many available grades of alnico magnets and you can see them below:

Sintered Alnico Magnets

450°C – Alnico 2, Alnico 5 and Alnico 8

Cast Alnico Magnets

500°C – Alnico 5, Alnico 5B, Alnico 5DG

525°C – Alnico 5-7, Alnico 8-HC, Alnico 8, Alnico 8B, Alnico 8C, Alnico 9

This means Alnico magnets range between 450°C and 525°C temperatures, which means they’re far superior than other permanent magnets. Although the coercivity is greatly improved, alnico magnets are not as magnetically powerful as neodymium or samarium cobalt magnets.

Coercivity of Ferrite / Ceramic Magnets

Ferrite magnets have some very unique properties that make them ideal for many applications. Although they have the lowest MGOe (maximum energy product), they have excellent coercivity which means they withstand demagnetisation forces (such as heat) far better than many other magnetic materials. In fact, when ferrite magnets get hotter, their inherent coercivity increases which is one of the reasons why ferrite magnets are so popular.

The increase in inherent coercivity increases by approximately 0.4% for every degree the heat is increased. However, the magnetic output decreases by approximately 0.2% for every degree the heat is increased. These effects return to the original state once the temperature returns back to normal. If you’re looking for a powerful magnet that operates well in extreme temperatures, Alnico, SmCo or high temperature neodymium magnets is recommended.

You can see the magnetic properties of ferrite magnets by clicking here.

All Grades – Max Temperature of 180°C

Y8T, Y10T, Y20, Y22H, Y23, Y25, Y26H, Y26H-1, Y26H-2, Y27H, Y28, Y28H-1, Y28H-2, Y30, Y30BH, Y30H-1, Y30H-2, Y32, Y32H, Y32H-1, Y32H-2 Y33, Y33H, Y34, Y35, Y36, Y38 and Y40.

What is Magnetic Coercivity?

The term coercivity refers to the ability of a ferromagnetic material to hold magnetism and withstand changes to it’s magnetic field. These changes include magnetisation as well as demagnetisation.

To magnetise this material, it is hit with a strong magnetic field, thus ‘coercing’ magnetism within that material. This is the technical definition of coercivity. However, it’s most often used to refer to a magnets ability to withstand demagnetisation.

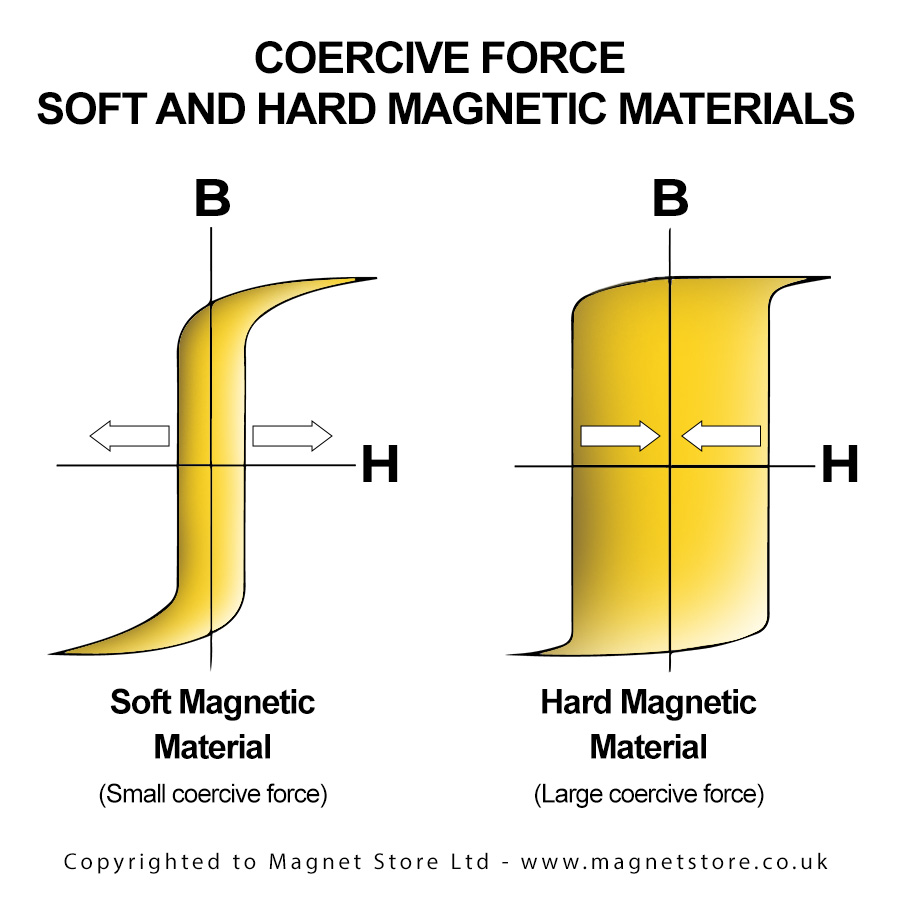

Coercivity can be measured by determining how much external magnetic field is required to reduce a magnetic field to zero. This is mathematically broken down as the amount of negative (H) needed to reduce (B) to zero. This process of measuring a magnetic field is measured in oersted or tesla.

When magnets are manufactured, the magnetisation process happens near the end of production. This means the shape, coating (if applicable), and overall aesthetics of the magnet are finished before the material is even magnetic. The non-magnetised materials are magnetised by applying a magnetic field – this is where the magnets poles become magnetised.

Coercivity of Soft and Hard Metals

Materials that can be permanently magnetised are known s “magnetically hard”, including alnico, ferrites, rare earth cobalt, neodymium iron boron (NdFeB). On the other hand, materials that are considered as “magnetically soft” are materials that are less effective at retaining magnetism. This means they have a much weaker magnetic field. Magnetically soft materials include iron-silicon alloys and nickel-iron alloys

Hard Magnetic Material: A hard magnetic material is very effective at resisting demagnetisation, thus not becoming demagnetised easily.

Soft Magnetic Material: A soft magnetic material is less effective at resisting demagnetisation thus becoming demagnetised easily.

Measuring Magnetic Coercivity

Magnetic coercivity is usually measured by using empirical or numeric methods. They’re often measured by the magnetization curve which can be found through analysis of the hysteresis loop of a chosen material. The data generated by the hysteresis loop can be interpreted through the use of an oscilloscope. An oscilloscope is an electronic test instrument that displays electrical voltages, thus giving you a visual representation of the data.