Shop Mitre Magnets:

Mitre Magnets, with precise angular cuts, are designed for specialised alignment applications. Their mitre angle ensures perfect corner connections, essential for seamless joints. Ideal for advanced robotics, precise framing, and custom cabinetry, these magnets offer strong magnetic pull for secure, discreet corner holding in carpentry, model building, and art installations. Their angular versatility ensures consistent alignment and attachment at specific angles, enhancing functionality and aesthetics in various projects. Discover the precision and utility of Magnet Store’s Mitre Magnets for your specialised angular magnetic needs.

Shop Mitre Magnets

Mitre Magnets, with precise angular cuts, are designed for specialised alignment applications. Their mitre angle ensures perfect corner connections, essential for seamless joints. Ideal for advanced robotics, precise framing, and custom cabinetry, these magnets offer strong magnetic pull for secure, discreet corner holding in carpentry, model building, and art installations. Their angular versatility ensures consistent alignment and attachment at specific angles, enhancing functionality and aesthetics in various projects. Discover the precision and utility of Magnet Store’s Mitre Magnets for your specialised angular magnetic needs.

-

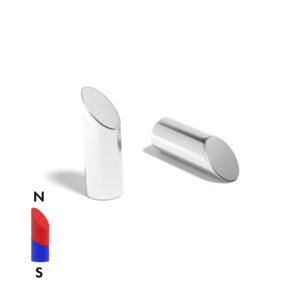

10mm x 30mm Neodymium Mitre Magnet N52 – North (7.51KG Pull)

£8.50 – £816.99 -

10mm x 30mm Neodymium Mitre Magnet N52 – South (7.51KG Pull)

£8.50 – £816.99 -

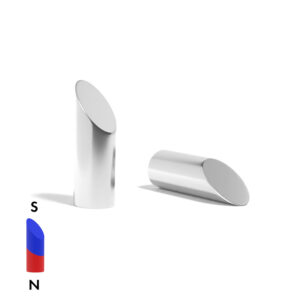

20mm x 60mm Neodymium Mitre Magnet N42 – North (19.52KG Pull)

£51.29 – £1,899.99 -

20mm x 60mm Neodymium South Mitre Magnet N42 (45.25KG Pull)

£51.29 – £1,899.99

Mitre Magnets FAQs

What are Mitre magnets and how are they different from regular magnets?

Mitre magnets are specifically engineered with angular cuts, typically at 45 degrees, allowing them to seamlessly fit together at corners or edges. Unlike regular magnets that have straight edges, Mitre magnets are ideal for applications requiring precise angular alignment, providing a smooth and continuous magnetic force along the joints they form.

How do I install Mitre magnets in a frame or fixture?

To install Mitre magnets in a frame or fixture, start by measuring and marking the precise locations on the angled surfaces where the magnets will be embedded. Next, carefully drill recesses at these marks to accommodate the shape and size of the Mitre magnets, ensuring each recess allows for a flush fit. Once the recesses are prepared, secure the magnets in place using a suitable adhesive to maintain a strong and permanent hold. Finally, verify that the magnets are correctly aligned to ensure they connect properly and provide the desired magnetic functionality.

How do I ensure I purchase two magnets that attract on the mitre side?

To guarantee that two Mitre magnets attract each other on their mitre sides, it is crucial to select magnets with compatible magnetisation directions. Each product listing provides specific information on the magnetisation direction, allowing you to choose the appropriate pair that will attract correctly when aligned. If two magnets from the same product page are purchased, they will repel from the mitre side. Always check this information on the product page before making a purchase.

Can mitre magnets be customised for specific angular cuts, other than 45 degrees?

Absolutely, Mitre magnets can be customised to meet specific project requirements. We offer customisation in terms of the angle of the mitre, size, coating, grade of magnetic power, magnetisation direction, and even temperature tolerances. This flexibility ensures that you receive a magnet tailored exactly to your specifications, ideal for unique applications.

How are Mitre magnets tested for quality and performance?

Our Mitre magnets are ROHS and REACH certified, ensuring they meet stringent European standards for safety and environmental impact. Each magnet undergoes rigorous quality control (QC) procedures to verify its precision and performance. This diligent testing ensures that you receive only the highest quality magnets for your applications.

What safety precautions should I take when handling Mitre magnets?

Handling Mitre magnets requires caution due to their strong magnetic force. Always wear protective gloves to prevent pinching and keep the magnets away from electronic devices to avoid damaging them. When moving large or very strong magnets, ensure that you keep them at a safe distance from each other to prevent sudden and forceful attractions that could cause injuries.

Can't find what you are looking for?

Get in touch if you can’t find what you’re looking for – a member of our team will be happy to help.