Permanent Magnetic Materials

Learn about the most popular permanent magnets.

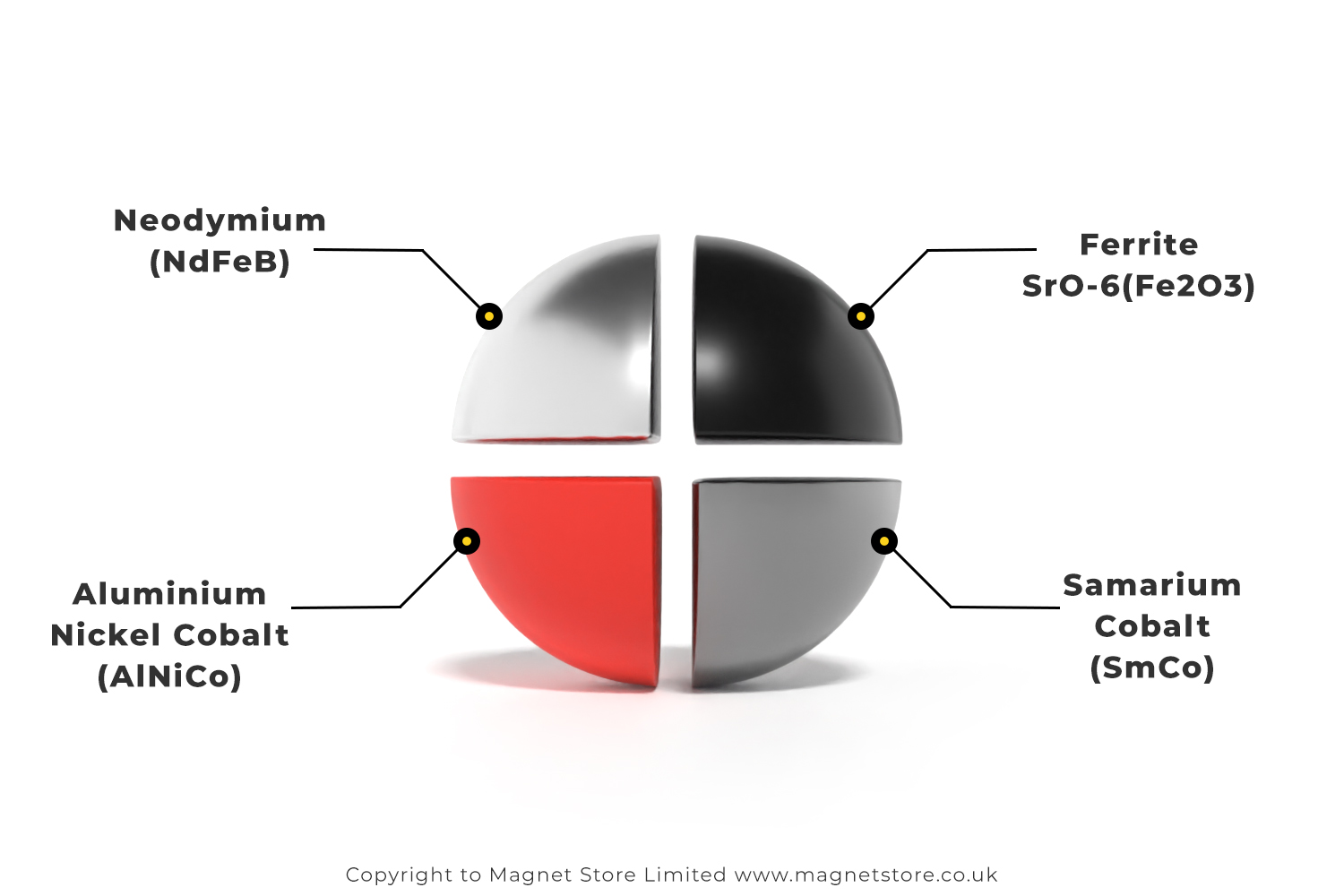

Types of Magnetic Materials

All major permanent magnets are currently made from four different types of magnetic materials; neodymium, samarium cobalt, alnico and ferrite / ceramic.

Each of these magnets have different properties which make them ideal for certain applications. The most common are neodymium magnets because of their high power to size ratio.

Magnetic Materials

What are Neodymium Magnets?

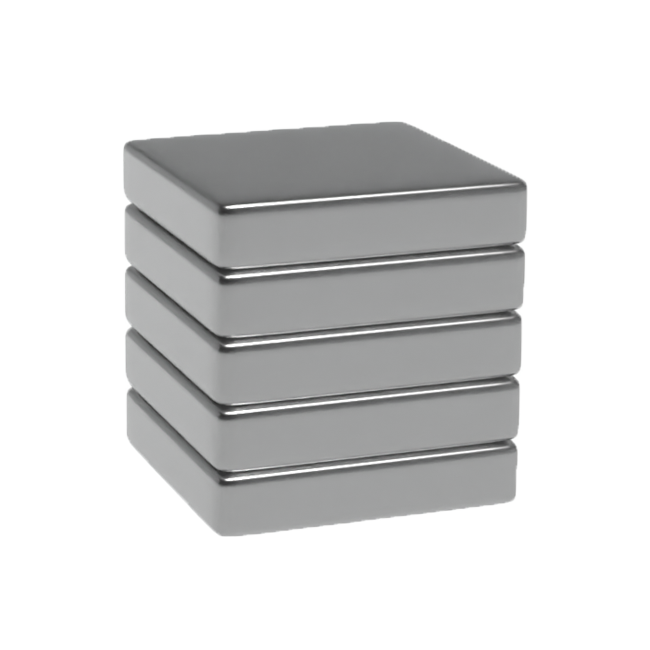

Neodymium magnets (NdFeB) are one type of rare earth magnets that are produced from an alloy of Neodymium, Iron and Boron. These form the tetragonal crystalline structure Nd2Fe14B and were originally developed in 1984 by General Motors and Sumitomo Special Metals.

#Neodymium magnets are the most powerful permanent magnets available and they’re used many modern technologies such as generators, electric motors, sensors, magnetic lock mechanisms, computers, machinery and much more.

Raw neodymium is prone to corrosion when exposed to humid or wet environments, so most neodymium magnets have a protective coating to increase longevity. The most common coating is Ni-Cu-Ni (nickel copper nickel plating), however, there are lots of coating options to choose from depending on your use – you can see these coating options here. Alternatively, you can shop our general neodymium range here.

What are Samarium Cobalt (SmCo) Magnets?

Another type of permanent rare earth magnet is the samarium cobalt magnet. Samarium cobalt magnets are made from an alloy of samarium and cobalt (SmCo) and they were first developed in the 1970s. They have a hexagonal crystalline structure which give them highly directional magnetic properties which make them one of the strongest types of permanent magnet available, second to Neodymium magnets.

SmCo magnets have far better resistance to demagnetisation forces than neodymium magnets. This means they can retain their magnetic properties when exposed to high temperatures or strong magnetic fields. And yes, strong magnetic pulses can demagnetise magnets. A magnet’s resistance to demagnetisation is often referred to as the magnetic coercivity and you can read about it here.

What are Alnico Magnets?

Alnico magnets are permanent magnets made of aluminium, nickel, and cobalt. They were first invented in the 1930s and were widely used in motors due to their high magnetism and excellent resistance to demagnetisation (high coercivity).

Alnico magnets are not as magnetically powerful as neodymium or samarium cobalt magnets. This is one of the reasons why their popularity has slowly decreased since the 70s and 80s, but they are still widely used for certain applications. Although alnico magnets are not as powerful as neodymium or SmCo magnets, they are more powerful than ferrite magnets and they perform much better than all other kinds of magnets in hotter temperatures.

Alnico magnets are found in many technologies that still surround us to this day, such as electric guitar pickups, travelling wave tubes, sensors and speakers – to mention a few. However, Alnico magnets are brittle and can break easily so it’s best to avoid high impact collisions.

What are About Ferrite / Ceramic Magnets?

Ferrite magnets were invented in 1930 and they are a type of permanent magnet made from ferrite, a compound of iron and other materials. Although they have a weaker magnetic field than neodymium, SmCo and Alnico magnets, they are still strong enough to be used in many applications, including motors, generators, and speakers.

Ferrite magnets have have excellent resistance to demagnetisation forces, but they are still fragile and can still split when exposed to significant physical impact.

Ferrite magnets are the most commonly used magnets for fridge magnets. This is because they are low cost, they’re easy to mass produce and do not need a powerful magnetic field. The low cost means they’re perfect for applications that may be on a tight budget. They also perform excellent in hot conditions but they are not recommended to be used in cold conditions.

What Can You Customise?

What is a Magnet?

Magnets are objects that create a magnetic field. Magnets are made from materials that have unpaired electrons in their atoms, when these unpaired electrons align, they create a magnetic field which is invisible to the human eye. This magnetic field then interacts with other magnets and some metals (if ferromagnetic) creating a force, which will either attract or repel an object.

What Are Permanent Magnets?

A permanent magnet is an entity made from a magnetic elements that is magnetized and create its own constant magnetic field. These magnets are highly resistant to having their magnetic field removed.

Hard and Soft Ferromagnetic Materials

Ferromagnetic materials can be broken into magnetically soft materials which emit a weak magnetic field and unlikely to stay magnetized for a prolonged period of time. Hard materials can sustain magnetism indefinitely, unless they are effected by other forces like extreme temperatures, magnetic pulses, kinetic force or an external opposing magnetic field.

Permanent magnets are made from magnetically hard materials, they are difficult to magnetise due to their atomic magnetic domains, but once they are magnetised, they are permanent. For this reason, they are the ideal magnet to use for industrial purposes and are generally made from alloys such as iron, aluminium, nickel and cobalt, and rare earth elements such as neodymium, dysprosium and samarium.