Bespoke Industrial Magnetic Assemblies

Specialists in bespoke magnetic solutions, we combine expert engineering with elite manufacturing to deliver superior performance and value.

Types of Magnetic Assemblies

Our assemblies are grouped by function to help you find the perfect solution for your needs. Click each category to explore specific product types.

Holding and Fixturing Assemblies

The foundation for static clamping of ferrous materials in industrial settings.

Pot Magnets

- Structure: A permanent magnet (e.g. NdFeB, ferrite etc.) encased in a steel pot to concentrate flux on one face for extreme holding force.

- Use Cases: Workholding jigs, industrial automation, cabinet closures, and retail displays.

- Performance: High pull force, temperatures up to 350°C and corrosion protection dependent on material

- Integration: Round shapes (10mm-120mm) with countersunk holes or threaded studs.

Channel Magnets

- Structure: Rectangular magnets (Ferrite or NdFeB) in a U-shaped steel channel.

- Use Cases: Tool racks, CNC fixturing, conveyor guide rails.

- Performance: Strong shear force, resistant to demagnetization.

Magnetic Bases & Lifters

- Structure: Switchable permanent magnet (often electro-permanent) in a robust housing.

- Use Cases: Positioning dial indicators, lifting heavy steel plates safely.

- Performance: Fail-safe holding (no power required), lifting capacity up to several tons.

Separation and Sorting Assemblies

Serving mature processing industries with stable demand for purity and recovery.

Magnetic Separator Grids

-

Structure: High-Gauss (10,000 to 13,500 Gauss) NdFeB tubes in a grid frame.

-

Use Cases: Removing metal contaminants in food processing and pharmaceuticals.

-

Materials: $NdFeB$ in 304 or 316L stainless steel tubes.

Drums, Pulleys & Overbands

-

Structure: Rotating drum or conveyor belt with powerful internal magnets.

-

Use Cases: Metal recovery in recycling plants, sorting ore in mining.

-

Materials: Primarily robust Ferrite magnets for large-scale applications.

Drive and Coupling Assemblies

Supporting contactless power transmission for automation and electrification.

Magnetic Couplings

- Structure: Inner and outer rotors with alternating magnets (SmCo or NdFeB) separated by a shroud.

- Use Cases: Zero-leakage pumps in chemical/pharma, mixers in oil & gas.

- Performance: Contact-free torque transmission, no wear, corrosion-resistant.

Magnetic Gears

- Structure: Interlocking magnet arrays transferring torque without physical teeth.

- Use Cases: High-precision robotics, wind turbine generators.

- Performance: High efficiency, low noise, built-in overload protection.

Magnetic Motion and Transport Assemblies

Linear Motor Guideways

Linear Motor Guideways

Structure: U-channel or flat-track arrangements using permanent magnets (typically NdFeB) mounted on steel backplates, facing ironless coil forcers suspended on low-friction bearings.

Use Cases: Robotic arms, CNC stages, semiconductor machinery, photonics alignment, fibre-optic assembly, and high-speed pick-and-place automation.

Performance: Frictionless linear drive with velocity regulation down to <0.1% ripple. Acceleration up to 15 m/s², high precision, no backlash or wear.

Integration: Available in scalable modular lengths (e.g. 30 × 360 mm), with brushless three-phase coils, air or water cooling, and encoder feedback.

Magnetic Transport Rails & Wheels

Structure: Flat or curved linear magnet tracks combined with guided magnetic rollers or wheels for smooth contactless conveyance.

Use Cases: Automated guided vehicles (AGVs), material handling systems, magnetic belt conveyors.

Performance: Silent operation, reduced maintenance, efficient movement of payloads without mechanical linkages.

Integration: Compatible with custom frame designs, air-bearing systems, and modular conveyor assemblies.

Rotor and Motor Assemblies

Key components in the expanding EV and industrial automation sectors.

High-Performance NdFeB Rotors

- Structure: Segmented arc magnets (e.g., N45SH grade) bonded to a shaft or housed in back-iron.

- Use Cases: Electric vehicle (EV) drivetrain motors, industrial servo motors, aerospace generators.

- Performance: High power density, tight tolerances, operational up to 150°C+.

- Materials: High-temperature NdFeB grades alloyed with Dysprosium (Dy).

Custom and Specialised Assemblies

Targeting niche, high-margin applications in extreme or specialised environments.

Halbach Arrays

- Structure: A specific arrangement of magnets that augments the field on one side while cancelling it on the other.

- Use Cases: Scientific particle accelerators, high-field MRI machines, high-efficiency motors.

- Performance: Highly uniform field, significantly reduced stray flux.

Encapsulated & Overmolded

- Structure: Magnets completely sealed in epoxy, plastic, rubber, or a welded steel shell.

- Use Cases: Marine holding magnets, downhole tools for oil & gas, sensors exposed to harsh chemicals.

- Performance: Fully moisture-proof and resistant to harsh environments.

Application by Industry

Automotive

Magnetic rotors, gears, and couplings for EV drive systems, battery cooling pumps, sensor mounts, autonomous safety modules, and much more.

Engineering

Pot magnets for precision jigs, channel magnets for modular fixturing, and switchable lifters for industrial automation and robotics.

Energy Generation

High-torque magnetic couplings and custom rotor assemblies for wind turbines, hydroelectric drives, and generator platforms.

Science and Research

Linear motor guideways, Halbach arrays, and encapsulated magnetic assemblies for laboratory equipment and experimental systems.

Oil and Gas

Magnetic filters, couplings, and sealed rotor assemblies for submersible pumps, chemical mixers, and downhole tool protection.

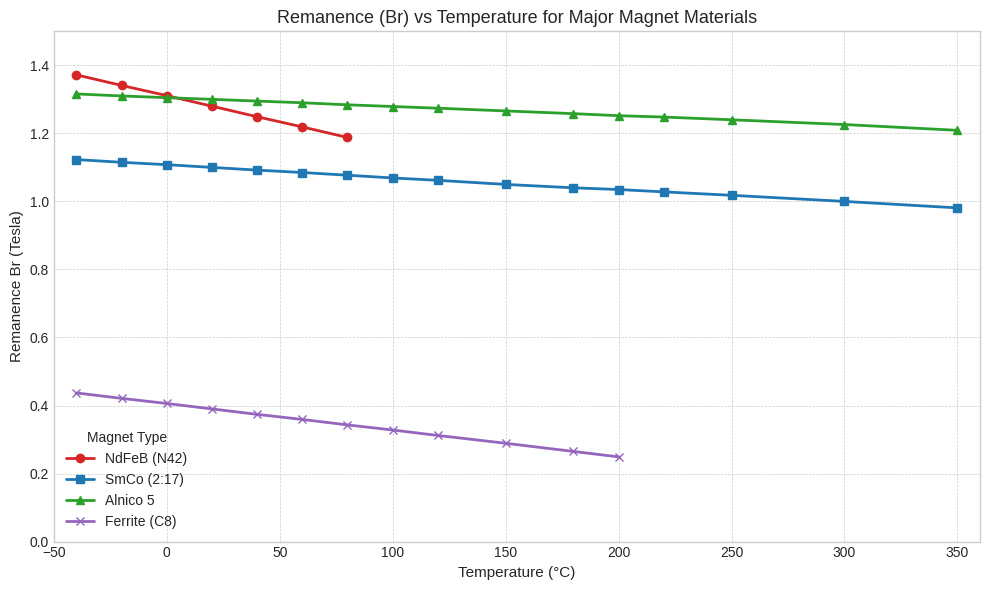

Magnet Remanence and Thermal Stability

| Characteristic | Neodymium (NdFeB) | Samarium Cobalt (SmCo) | Alnico | Ferrite |

|---|---|---|---|---|

| Max Energy Product | Highest | High | Medium | Low |

| Max Operating Temp. | Up to 230°C (with special grades) | Up to 350°C | Up to 550°C | Up to 250°C |

| Corrosion Resistance | Poor (requires coating) | Excellent | Excellent | Excellent |

| Common Use | Motors, Sensors, High-Strength Holding | High-Temp Couplings, Aerospace | High-Temp Sensors, Guitar Pickups | Large Separators, Low-Cost Holding |

Remanence (Br) vs Temperature for NdFeB, SmCo, Alnico and Ferrite Magnets: Scientific Comparison of Thermal Stability and Magnetic Performance.

Ordering Made Simple

1. Specification Review

You provide us with details, magnet requirements, and any key performance criteria needed for your application. Drawings may be required.

2. Quotation & Lead time

We review your brief and respond with a clear quotation and delivery timeframe based on production capacity and material availability.

3. Manufacturing

Your design and specifications are forwarded to the production team where it’ll begin manufacturing according to the agreed specifications.

4. Direct Dispatch

Once complete, you will recieve notification and your order is shipped directly to your address for one of the industry’s fastest, efficient delivery.

Request a quote...

What Makes Us Special?

Magnet Store is a leading specialist in magnetic solutions. Our expert team focuses on precision, quality, and client satisfaction, adhering to top industry standards. Trust our dedicated and innovative approach to fulfil your specific magnetic needs for any product or project.

Frequently Asked Questions...

What happens after I complete the form?

All information will be sent to our engineers to review. You’ll receive your quote within 1-3 business days (exception of national and some international holidays). Production will start once secure payment has been made.

How long will my order take to arrive?

We pride ourselves in having one of the fastest turnaround times in the industry, averaging 15 business days from payment.

What do Neodymium grades mean? (N35-N52)

The grades N35 to N52 refer to the maximum energy product, the higher the number the greater the magnetic field. Higher grades of Neodymium are generally more expensive, we find the N42 is the perfect balance between performance and cost.

What coating options are available?

We can offer most coating options. The most common coating for Neodymium magnets is Nickel and Cobalt (NiCuNi), but we also offer Zinc (Zn), Gold (Au), Rubber, Epoxy and Titanium (Ti), to name a few.

What if I have special requirements?

If you have requirements that aren’t mentioned in the form, please include as much information in the bottom fied. Our talented team of experts can help with almost any magnet requirements.

Can I choose the magnetisation direction?

Yes, you can choose the direction of magnetisation when ordering custom magnets.

The most common direction to magnetise magnets is axially. Axially magnetised magnets are magnetised through the length of the magnet, whereas diametrically magnetised magnets are magnetised through the width.

If you are unsure, please contact us and a member of our team will be happy to help.

What is the minimum order quantity?

We don’t have a minimum order quantity. However, our minimum spend for custom manufacturing is £100 due to design, moulding and manufacturing fees.

How are costs calculated?

The price of Neodymium goes up and down throughout the year and quotes are reflective of those changes. This means like-for-like quotes may differ throughout the year.

What are the size tolerance levels?

Tolerence levels determine slight differences in the size of your magnet. Our tolerance levels are 0.1mm+/-.

Can I choose heat tolerances?

Yes, we can produce magnets to most heat tolerences.

A magnet’s coercivity, or “Hci” refers to the magnets ability to withstand demagnetisation through high temperatures. When manufacturing magnets, a magnet’s coercivity is defined by the letters after the grade, for example, the “M” in N52M. Any magnets without a letter after the grade (i.e N35, N45, N52) have a heat tolerence of up to 80°C.

Available Heat Tolerences

- No letter – 80°C

- M – 100°C

- H – 120°C

- SH – 150°C

- UH – 180°C

- EH – 200°C

- TH – 220°C

What is the returns policy?

If you have a change of heart and would like to cancel your order our team will do everything in their power to help. If manufacturing has started we cannot refund your purchase because the custom order has no resale value.