Shop Disc Magnets:

High strength disc magnets, with their compact and powerful design, are essential for a wide range of applications. Ideal for use in electronics, consumer devices, sensors, precision instruments, and DIY projects, they provide cost-effective solutions with impressive strength and focused magnetic fields. Their versatility extends to hobbies and crafts, where they excel at securing closures and creating magnetic connections. Countersunk versions offer the added benefit of easy stitching. Experience the unmatched performance and reliability of Magnet Store’s disc magnets for all your industrial and creative needs.

Shop Disc Magnets

Disc magnets are the most commonly used magnets and serve as the foundation for many industries. With their compact and powerful design, they are vital in electronics, consumer devices, sensors, and precision instruments. Their reliability and efficiency make them essential in manufacturing, engineering, 3D printing, product design, and DIY projects. Experience the unmatched power and precision of Magnet Store’s neodymium disc magnets for all your industrial and DIY needs.

Showing all 59 results

-

10mm x 2mm Neodymium Disc Magnet N42 (1.19KG Pull)

£4.27 – £173.84 -

2mm x 1mm Neodymium Disc Magnets N42 (0.054KG Pull)

£4.37 – £70.29 -

3mm x 1mm Disc Neodymium Magnet N42 (0.10KG Pull)

£4.37 – £56.99 -

5mm x 1mm Disc Neodymium Magnet N42 (0.22KG Pull)

£4.49 – £63.93 -

5mm x 2mm Neodymium Disc Magnets N42 (0.47KG Pull)

£4.49 – £99.74 -

4mm x 1mm Disc Neodymium Magnet N42 (0.16KG Pull)

£4.49 – £75.99 -

5mm x 2mm Gold Plated Neodymium Disc Magnets N52 (0.58KG Pull)

£4.49 – £52.24 -

5mm x 1mm Neodymium Disc Magnet Gold Plated N52 (0.27KG Pull)

£4.49 – £37.04 -

4mm x 2mm Gold Plated Neodymium Disc Magnet N52 (0.42KG Pull)

£4.49 – £32.29 -

2mm x 2mm Neodymium Disc Magnet Gold Plated N54 (0.28KG Pull)

£4.65 – £19.66 -

3mm x 2mm Neodymium Disc Magnet Gold Plated N54 (0.62KG Pull)

£4.65 – £19.66 -

8mm x 1mm Neodymium Disc Magnet N42 (0.43KG Pull)

£4.74 – £152.94 -

6mm x 2mm Neodymium Disc Magnet N42 (0.59KG Pull)

£4.74 – £142.49 -

4mm x 4mm Disc / Cylinder Neodymium Magnet N42 (0.53KG Pull)

£4.74 – £142.49 -

6mm x 4mm Neodymium Disc Magnets N42 (1.10KG Pull)

£4.93 – £145.34 -

6mm x 3mm Disc Neodymium Magnet N42 (0.89KG Pull)

£4.94 – £189.99 -

8mm x 1.5mm Neodymium Disc Magnets N42 (0.71KG Pull)

£4.94 – £199.89 -

6mm x 1mm Adhesive Disc Neodymium Magnet N42 (Pull 0.29KG)

£4.94 – £189.99 -

10mm x 1mm Neodymium Disc Magnet N42 (0.56KG Pull)

£4.94 – £189.99 -

8mm x 3mm Neodymium Disc Magnet N42 (1.42KG Pull)

£5.03 – £199.49 -

5mm x 5mm Disc / Cylinder Neodymium Magnet N42 (0.92KG Pull)

£5.13 – £237.49 -

8mm x 1mm Adhesive Disc Neodymium Magnet N42 (Pull 0.43KG)

£5.22 – £189.99 -

8mm x 3mm x (3mm Hole) Countersunk Neodymium Magnets N42 (1.26KG Pull)

£5.69 – £379.99 -

8mm x 4mm Neodymium Disc Magnet N42 (1.79KG Pull)

£5.69 – £379.99 -

10mm x 2mm x (3mm Hole) Countersunk Neodymium Magnet N42 (1.90KG Pull)

£5.89 – £379.99 -

15mm x 1mm Disc Neodymium Magnet N42 (0.91KG Pull)

£5.89 – £360.99 -

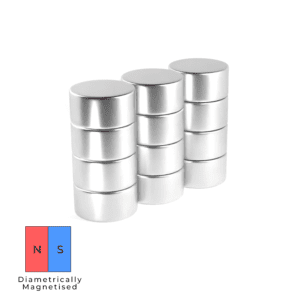

6mm x 3mm Disc Diametrically Magnetised Neodymium N52 (0.31KG Pull)

£5.98 – £165.29 -

10mm x 3mm Neodymium Disc Magnet N42 (1.96KG Pull)

£6.08 – £398.99 -

8mm x 2mm Gold Plated Neodymium Disc Magnet N52 (1.1KG Pull)

£6.17 – £74.09 -

15mm x 1mm Adhesive Disc Neodymium Magnet N42 (Pull 0.91KG)

£6.18 – £417.99 -

12mm x 2mm Adhesive Disc Neodymium Magnet N42 (Pull 1.54KG)

£6.46 – £474.99 -

8mm x 5mm Disc Black Epoxy Neodymium Magnet N42 (2.07KG Pull)

£6.64 – £455.04 -

12mm x 1mm Gold Plated Neodymium Disc Magnet N52 (0.87KG Pull)

£6.64 – £104.49 -

20mm x 10mm Neodymium Disc Magnet N42 (12.21KG Pull)

£6.74 – £1,139.99 -

15mm x 2mm (4.2mm Hole) Countersunk Neodymium Magnet N42 (1.95KG Pull)

£6.83 – £541.49 -

20mm x 1mm Neodymium Disc Magnets N42 (1.22KG Pull)

£7.13 – £626.99 -

10mm x 5mm x (3.2mm Hole) Countersunk Neodymium Magnet N42 (Pull 2.68KG)

£7.32 – £636.49 -

16mm x 2mm x (5mm Hole) Countersunk Neodymium Magnet N42 (2.09KG Pull)

£7.32 – £693.49 -

12mm x 4mm (3.5mm Hole) Countersunk Neodymium Magnet N42 (2.71KG Pull)

£7.79 – £879.99 -

11mm x 7mm Neodymium Disc Magnet N48 (4.71KG Pull)

£8.07 – £163.39 -

14mm x 3.6mm (3.5mm Hole) Countersunk Neodymium Magnet N42 (Pull 3.52KG)

£8.54 – £930.99 -

8mm x 1mm Disc Diametrically Magnetised Neodymium N52 (0.25KG Pull)

£8.54 – £154.84 -

12mm x 2mm Neodymium Disc Magnet Gold Plated N52 (1.9KG Pull)

£8.54 – £85.49 -

20mm x 3mm Neodymium Disc Magnets N38 (3.91KG)

£9.49 – £1,662.49 -

20mm x 3mm x (5mm Hole) Countersunk Neodymium Magnet N38 (Pull 3.81KG)

£9.49 – £1,044.99 -

10mm x 10mm Neodymium Disc / Cylinder Magnet N42 (4.02KG Pull)

£9.49 – £1,206.49 -

20mm x 3mm x (5mm Hole) Disc Countersunk Black Epoxy Neodymium Magnet N42 (Pull 4.21KG)

£12.83 – £1,899.99 -

20mm x 2mm Disc Black Epoxy Neodymium Magnet N52 (3.48KG Pull)

£12.84 – £1,358.49 -

10mm x 10mm Disc Diametrically Magnetised Neodymium N52 (2.52KG Pull)

£13.29 – £1,614.99 -

32mm x 5mm x (6mm Hole) Countersunk Neodymium Magnet N42 (Pull 13.49KG)

£13.78 – £6,174.99 -

15mm x 5mm Neodymium Disc Magnets N42 (5.48KG Pull)

£13.87 – £1,614.99 -

20mm x 5mm 3M Adhesive Disc Neodymium Magnet N52 (Pull 9.67KG)

£15.19 – £2,023.49 -

16mm x 3.5mm Neodymium Disc Magnets N42 (4.17KG Pull)

£18.04 – £2,090.00 -

18mm x 7mm x (4.5mm hole) Counterbore Neodymium Magnet N52 (Pull 10.1KG)

£28.49 – £1,196.99 -

24mm x 8mm x (5.5mm hole) Counterbore Neodymium Magnet N52 (Pull 16.5KG)

£38.94 – £2,241.99 -

25mm x 8mm x (5mm hole) Counterbore Neodymium Magnet N52 (Pull 17.5KG)

£40.84 – £2,279.99 -

30mm x 10mm x (5.5mm hole) Counterbore Neodymium Magnet N52 (Pull 26KG)

£66.49 – £4,654.99 -

32mm x 10mm x (6.6mm hole) Counterbore Neodymium Magnet N52 (Pull 27.7KG)

£66.49 – £4,654.99 -

40mm x 12mm x (6.6mm hole) Counterbore Neodymium Magnet N52 (Pull 40.3KG)

£104.49 – £3,514.99

Disc Magnets FAQ

What are disc magnets used for?

Disc magnets are integral components in various applications due to their versatile shape and powerful magnetic properties. In manufacturing, they are used to hold and secure components during assembly and fabrication processes. The electronics industry relies on disc magnets for the operation of sensors and switches, providing precise and reliable magnetic fields for detecting and activating devices. They are also essential in magnetic separation equipment, helping to remove ferrous contaminants from product streams and ensuring product purity. In the production of electric motors and generators, disc magnets enhance efficiency and performance with their strong magnetic fields. Automation and robotics benefit from disc magnets as they create magnetic couplings and mounts, enhancing the flexibility and functionality of robotic systems. Packaging machinery utilises disc magnets to control and stabilise moving parts, ensuring precision in labelling and sealing processes. By leveraging the strength and reliability of disc magnets, businesses can improve efficiency, precision, and product quality in their operations.

How strong are disc magnets?

The strength of a disc magnet depends on its size and the material it is made from. Neodymium disc magnets, for instance, are among the strongest available, with some small discs being able to hold up to several kilograms of weight. Whereas ferrite magnets are lower in strength. Each Strength is usually measured in terms of pull force or magnetic flux density (measured in Gauss or Tesla).

Are disc magnets safe to use?

Disc magnets are generally safe to use, but they can be hazardous if not handled properly. They can snap together with great force, potentially causing injury. Small magnets can be a choking hazard and are extremely dangerous if swallowed, as they can cause serious internal damage. It’s important to keep them away from children and electronics, as their strong magnetic fields can damage devices like pacemakers and credit cards so please use them appropriately.

Can disc magnets lose their magnetism?

Yes, disc standard magnets can lose their magnetism over time or if they are exposed to certain conditions. Factors that can cause a loss of magnetism include high temperatures, strong opposing magnetic fields, physical damage, and corrosion. However, high-quality disc magnets, especially those made from neodymium, typically retain their magnetism for many years under normal conditions. If you require magnets that can withstand higher temperatures of corrosive environments please get in touch we can manufacture custom disc magnets to meet your needs.

What are the differences between neodymium and ferrite disc magnets?

Neodymium disc magnets are much stronger than ferrite (ceramic) disc magnets and are usually smaller for the same amount of strength. Neodymium magnets are more expensive and can corrode easily without a protective coating, whereas ferrite magnets are cheaper, more resistant to corrosion, but much weaker. Neodymium magnets are typically used in high-performance applications, while ferrite magnets are suitable for general use where high strength is not critical.

How can disc magnets be used in DIY projects?

Disc magnets are popular in DIY projects due to their strength and ease of use. They can be used for creating magnetic closures for boxes and cabinets, in homemade tools, for securing items in workshops, in educational models to demonstrate magnetic principles, and even in creative art and craft projects.

Can you drill disc magnets?

Drilling disc magnets is generally not recommended. The material they are made from, especially neodymium, is very brittle and can easily crack or shatter under the stress of drilling. Additionally, drilling generates heat, which can demagnetise the magnet. If a hole is needed in a disc magnet, it is best to purchase magnets that are pre-drilled. If drilling is unavoidable, it should be done very slowly and with cooling to minimise heat build-up, but this still carries a high risk of damaging the magnet. If you are unable to find a countersunk or counterbore disc magnets that meets your need please get in touch and we can manufacture them for you.

Can't find what you need?

If you can’t find what you’re looking for, please get in touch and a member of our team will be happy to help.