How are Neodymium magnets made?

Neodymium is a rare earth magnet that has some of the strongest magnetic properties on earth. These are a form of permanent magnets (ndfeb magnets) and can be manufactured to any shape or size. Here, you’re going to learn how sintered Neodymium magnets are actually made.

But first, it’s important to have a clear understanding of what “sintered” actually means. “Sinter” means heat treating material to ensure it is compact and in solid form. This is relevant to Neodymium magnets because the correct materials are grinded, heated and compressed to form a solid material.

The material is then magnetised through a machine that produces magnetic pulses. The final product is what we call sintered Neodymium magnets.

Now we’ve explained what sintering is, read on below to see all of the steps required to produce sintered Neodymium magnets.

1. Preparation of Raw Materials

The most common Neodymium magnets (Nd2Fe14B ) include high quantities Neodymium (Nd) Iron (Fe) and Boron (B). These elements together form the Nd2Fe14B tetragonal crystalline structure. The Neodymium rare earth element is the magnetic material.

Standard Neodymium magnets operate up to 80°C so coercivity can be increased during the manufacturing process. But what actually is coercivity? Coercivity is the magnets resistance to external factors that can otherwise decrease the (BH)max or magnetic performance of a magnet. For example, these factors can include excessive heat, kinetic force and applying alternate currents.

Additional elements are added for magnets that have higher levels of coercivity/temperature tolerance. When small amounts of Iron (Fe) are replaced with Cobalt (Co), the coercivity increases at elevated temperatures.

If small portions of Neodymium (Nd) are replaced with Dysprosium (Dy), the intrinsic coercivity is improved. In turn, this means the maximum energy product (BHmax), or magnet’s ‘strength’ decreases. Cobalt and Dysprosium are commonly used together.

2. Vacuum Induction Furnace

The materials are melted in a vacuum induction furnace which generates electrical eddy currents. The materials are melted in a vacuum to prevent contaminants from entering the chamber.

3. Jet Milling

Jet mills grind materials together by using pressurised gases to accelerate and smash particles together.

Hydrogen decrepitation is another that accelerates very small hydrogen particles to penetrate grains of metal which significantly reduces their size. This reduces the particle size to 3-5 micrometers in diameter. The milling process is a very important stage in the manufacturing process because the powder can be compressed into shape.

4. Pressing

In a technique known as die-upsetting, the powder is compressed at elevated temperatures of approximately 725°C. The compressed object is then placed in a second die where it is compressed into a wider shape. This is about half its original height which aligns the direction of magnetization parallel to the pressing direction.

Another method of pressing is called isostatic pressing which applies equal pressure in all directions to form a solid with complete uniformity. This method is the best for magnetic performance regarding Neodymium magnets.

5. Sintering

Sintering is a common process in powder metallurgy. This process forms a solid mass of material by using heat and/or pressure. The temperature doesn’t go high enough to liquify the solids. The material is compressed at very high temperatures up to 1080°C, however, this is still below the material’s melting point so will not liquify.

At these temperatures, the particles adhere to each other forming a solid singular object.

6. Machining

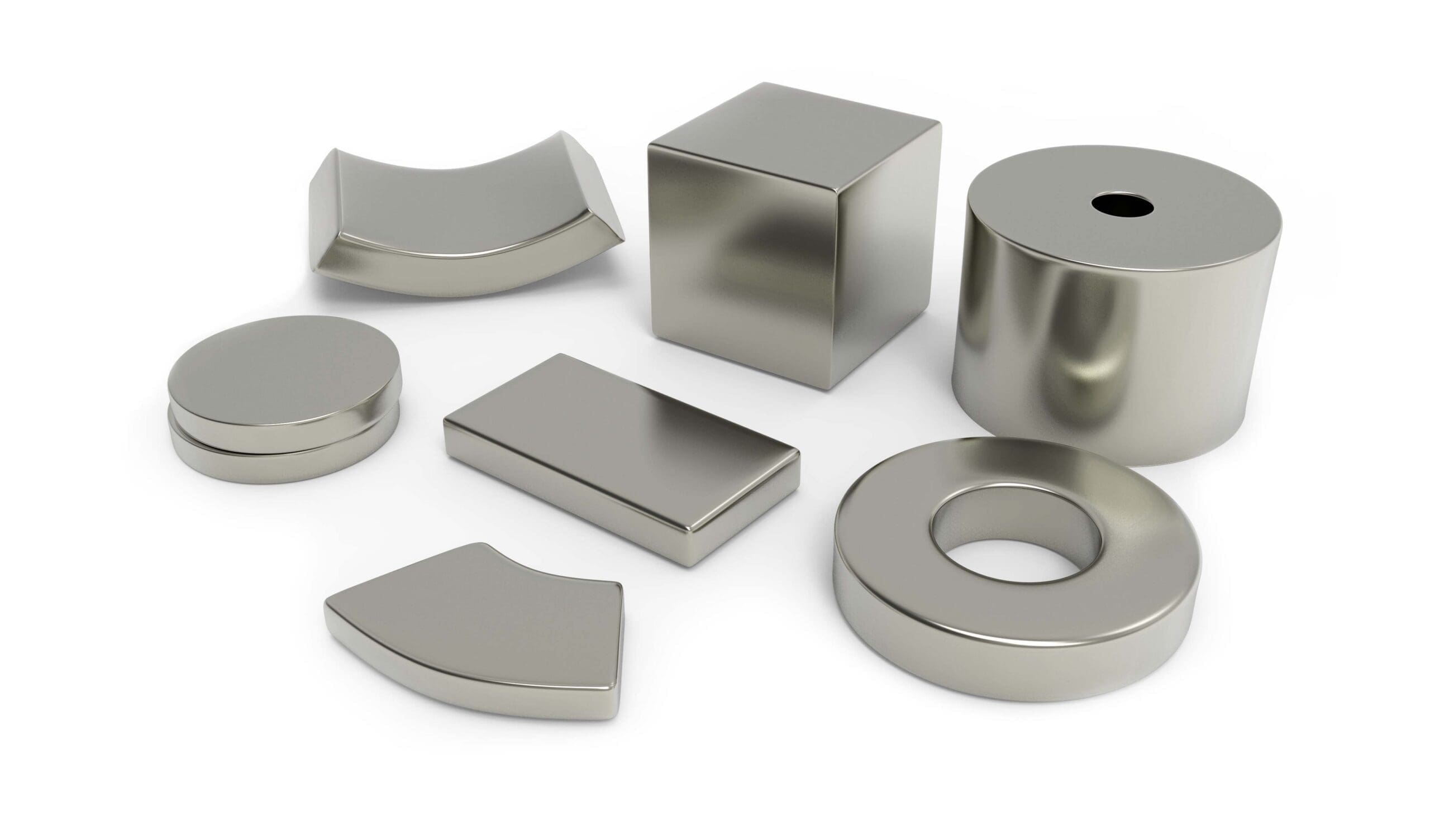

The machining process cuts the sintered magnets into the desired shape using a grinding and wire cutting process. Complex shapes are made with electric discharge machining (EDM). An EDM is the process of metal fabrication to produce a desired shape by using electrical charges. High material costs mean each product is efficiently cut to keep material losses at a minimum.

7. Plating

For most Neodymium magnets, individual magnets are electroplated with three layers of elements – nickel, copper and another layer of nickel (Ni Cu Ni). The plating process is a necessary step because neodymium magnets that don’t have protective coating are vulnerable to corrosion. This vulnerability could ultimately lead to their loss of magnetic properties due to moisture penetrating and corroding the materials.

Defective magnets will be put through a strip casting process to remove their plating. Once the initial plating has been removed the replacement can be applied. The process of stripping NdFeb magnets is usually a chemical or physical stripping process. The required stripping process is dependent on the material of coating being treated.

8. Magnetisation

At this point, the magnets have a “preferred” direction of magnetization, but they are not magnetized. They are placed in a fixture that will expose the magnet to a very strong magnetic pulse for a brief moment. This machine produces an external magnetic field which is a large coil of wire surrounding the magnet(s).

The magnetizing equipment use capacitors and very large electrical power volts to generate a strong magnetic pulse. This process magnetises the magnet(s) inside.

9. Quality Control

Once all processes are complete, the new Neodymium magnets are inspected for numerous things. Firstly a coating thickness measurement system uses x-ray fluorescence technology to confirm the thickness of the plating.

Secondly, a digital measuring projector confirms the dimensions are correct. The performance of the coating is then measured using a salt-spray and pressure cooker test. Lastly, a hystersigraph is used to measure the BH Curve of the magnets. This is what is used to confirm the grade and magnetisation of the magnet.

10. Delivery

Once the sintered magnet has been produced, it is then shipped to our warehouse for the final quality assessment. Once the magnets have passed the quality assessment, our packing team will pack and ship the goods to the client.

We take great pride in having one of the fastest turnaround times in the industry. The estimated lead time averages 15 business days, however, holidays and some international holidays can affect these delivery times. More complicated designs can increase the lead time.

How to custom order…

Here at Magnet Store, we can solve all of your magnetic needs. We can deliver sintered Neodymium magnets in almost every shape and size. This includes magnet block, disc, sphere, countersunk, rod, arc shapes and the client has full control of the coating and grade. Additionally, we also have the expertise to produce Alnico, Praseodymium, SmCo and ceramic magnets.

If you would like to purchase custom manufactured magnets, we’re happy to help. Click the button below go to our custom order page. Please complete the form and our team will be in touch with a quote and estimated time of arrival. Manufacturing begins after secure payment has been made.

Our team of experts offer continuous support through the whole process to ensure you receive exactly what you’ve requested.

Neodymium Magnets FAQ

What are Neodymium Magnets?

Neodymium Magnets (NdFeb) are a rare earth metal that has incredibly strong magnetic properties. These permanent magnets are the strongest magnets known on earth and have a magnetic force more than 10x stronger than traditional fridge magnets. This attribute makes them incredibly dynamic and practical to work with and has led to the innovation of many new technologies in the 20th and 21st century.

How are Neodymium magnets made?

Neodymim magnets are manufactured with the following machines and methods; strip cast, jet mill, press, sintering, grinding, wire cutting, plating and magnetisation.

What is the difference between grades N35, N42, N45, N52?

Grades of Neodymium range from N35 to N52. The number after the letter represents the maximum energy product, magnetic density, or ‘power’ that a magnet has. The higher the number, the stronger the magnet.

How quickly are orders dispatched?

All off-the-shelf orders are dispatched as quickly as possible. Our team will ensure all orders placed before 1pm (Monday – Friday excluding bank holidays) are sent the same day. Each packer will inspect the item quality as they are packing and dispatching order to ensure you receive only the best quality goods. If you have any questions regarding your order our friendly team are available to help 9:00 – 17.00 Monday to Friday so please get in touch via our contact page.

What is the lead time for custom manufacturing?

We pride ourselves in having one of the fastest lead times in the industry averaging at just 15 business days. More compicated products may take additional time and UK holidays and some international holidays may affect lead times on custom manufacturing.

Can heat destroy Neodymium magnets?

Standard Neodymium magnets have a heat tolerance of 80°C and exposing them to temperatures higher can affect the magnet. The performance of the magnet can restore once cooled unless the temperature raised to the Curie temperature, which is the temperature that magnets permanently lose their magnetic properties.

We can custom manufacture Neodymium magnets to withstand up to 220°C. Please see section below for more information.

Can I choose heat tolerances?

A magnet’s coercivity, or “Hci” refers to the magnets ability to withstand demagnetisation through high temperatures. When manufacturing magnets, a magnet’s coercivity is defined by the letters after the grade, for example, the “M” in N52M. Any magnets without a letter after the grade (i.e N35, N45, N52) have a heat tolerence of up to 80°C.

Available Heat Tolerences

- No letter – 80°C

- M – 100°C

- H – 120°C

- SH – 150°C

- UH – 180°C

- EH – 200°C

- TH – 220°C

Are you a UK based company?

Yes, Magnet Store is a limited UK company and we are based in Greater Manchester. Europe has no Neodymium quarries so all Neodymium magnets are produced overseas.

When was Neodymium discovered?

Although Neodymium was discovered in 1885 by Karl Auer, it was only in 1983 that Neodymium Magnets as we know today was invented almost simultaneously by General Motors and Sumitomo Special Metals and these strong and versatile magnets have spearheaded innovation in the green energy, medical and technology sector. These Neodymium magnets are small but generate an incredible amount of power and it’s this power that led to the miniaturization of many technologies like drills, heavy machinery, smart phones, sound speakers, computers and many more. They are commonly used in industries such as retail, engineering, plastic moulding, DIY, crafts, furniture making, science research & experimentation, education and many more.